There are extremely high safety standards in air travel. Everything is designed to make each trip safe for everyone involved. The number of air traffic accidents falls each year, despite the fact that the number of flights is consistently increasing. Statistics show that descent and landing are the most risky parts of a journey. Therefore ICAO requirements state that any structure located within 240m from the end of the runway, and within 60m of either side of the runway must be both of low mass and frangible. There are very few materials that can match these specifications, while still being viable for airport applications. This is where the choice to use fibreglass (fiberglass) comes in. It is the superior choice for frangible structures in airfield applications for several reasons.

Frangibility

Fibreglass (fiberglass) is designed to break upon impact, which is a key characteristic for frangible structures in airfield applications. These structures are made to break or yield when struck by an aircraft. This reduces the risk of severe damage to the aircraft and enhances safety.

No communication obstruction

Fibreglass (fiberglass) doesn’t obstruct radio frequency signals. This means airport operators don’t have to worry about any critical communications being blocked.

Energy absorption

Fibreglass (fiberglass) has good energy absorption properties. When an aircraft strikes a frangible fibreglass (fiberglass) structure, the material absorbs a significant portion of the kinetic energy, reducing the force of the impact. This can help protect the aircraft and its occupants.

Reduced risk of fire

Fibreglass (fiberglass) is non-metallic and non-conductive, so it does not produce sparks or conduct electricity. This reduces the risk of fire or electrical hazards when an aircraft makes contact with a frangible fibreglass (fiberglass) structure.

Lightweight and durable

Fibreglass (fiberglass) is a lightweight material, which is advantageous for frangible structures. Being lightweight makes it easier to engineer structures that break away upon impact. It reduces the risk of debris causing damage to the aircraft. However, despite being designed to break, fibreglass structures are durable and can withstand various environmental conditions. This includes exposure to sunlight, moisture, and temperature fluctuations. This durability ensures that the structures remain effective over time.

Low maintenance and cost-effectiveness

Fibreglass (fiberglass) frangible structures typically require less maintenance than metal alternatives. They do not corrode, which is very important in outdoor airfield environments where structures are exposed to the elements. They are designed to withstand temperatures ranging from -50 to +80 degrees celsius. Their durability reduces the need for frequent replacements. It’s true that fibreglass (fiberglass) may have a higher upfront cost than some other materials. However the durability and reduced maintenance requirements often means that fibreglass (fiberglass) proves more cost-effective in the long run.

Design flexibility

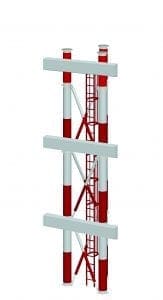

Fibreglass (fiberglass) can be moulded into various shapes and sizes. So, custom frangible structures can be created, that can be tailored to the specific needs and safety requirements of an airfield.

Environmental friendliness

Fibreglass (fiberglass) is considered more environmentally-friendly than certain metals. Its production generates fewer pollutants and it can be recycled.

—–

In airfield applications, frangible structures are strategically placed to break away upon impact with an aircraft. This significantly minimises the potential for severe damage. Also the safety of both the aircraft occupants and the people and infrastructure on the ground is protected. Fibreglass’ (fibreglass’) combines frangibility, energy absorption, and other desirable properties. Therefore its the preferred choice for maintaining the high safety standards in the aviation industry.

Why choose Pollite?

Pollite are one of the largest manufacturers of fibreglass (fiberglass) masts in Europe. Our fibreglass (fiberglass) structures are manufactured in the North East of England.

We are proud to have an international presence, having worked on projects across Europe, Asia, South America, the Middle East and Australasia. Contact us to discuss your requirements.