Glass Reinforced Plastic (GRP) fencing has emerged recently as a compelling choice in fencing solutions. It offers a unique blend of strength, low maintenance, and modern aesthetics. There are many benefits of GRP fencing, including versatility and durability. It is gaining popularity in various sectors, in particular on the airfield.

The Material

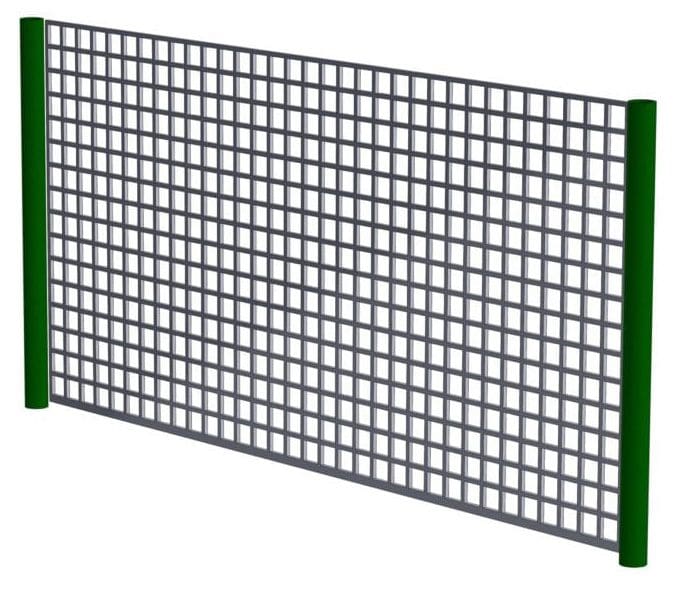

GRP, or Glass Reinforced Plastic, is a composite material made by reinforcing plastic with fine fibres of glass. This combination results in a material that is lightweight, strong, and corrosion-resistant. Frangible fencing uses these qualities to provide a durable and aesthetically pleasing alternative to traditional fencing materials.

Key Features

Strength and Corrosion Resistant

GRP fencing is known for its high strength-to-weight ratio, making it sturdy and durable. It withstands environmental elements, including harsh weather conditions, without corroding or deteriorating. This makes it an ideal choice for use in coastal areas or areas of high humidity.

Lightweight

GRP’s lightweight nature simplifies installation and transportation. It doesn’t compromise on strength, offering the convenience of easy handling during the installation process.

Low Maintenance

GRP requires minimal maintenance compared to traditional materials like wood or metal. It doesn’t need painting or coating to protect against the elements, contributing to long-term cost savings.

UV Resistance

GRP is inherently UV resistant, ensuring that the colour and finish of the fencing remain vibrant over time. This resistance to fading is particularly valuable in outdoor applications.

Electrical Insulation

GRP is an electrical insulator, making it suitable for fencing applications where electrical conductivity could pose a risk. This enhances safety, especially in industrial or utility settings.

Environmental Sustainability

GRP fencing is eco-friendly as it can be recycled, reducing its environmental impact. The production process also tends to be very energy-efficient.

Applications

Airfields

GRP fencing is commonly used in or around an airfield. Here, protective fencing is required to be frangible in accordance with ICAO regulations. Frangible fencing used by Pollite is manufactured from FRP and GRP composites. This ensures a durable system that resists extreme weather and pollutant environments. It is ideal for surrounding sensitive equipment at an airfield.

Perimeter Security

Frangible fencing is commonly used for securing perimeters, whether around commercial properties, residential complexes, or industrial facilities. Its durability and resistance to tampering make it an effective security solution.

Landscaping and Gardens

The aesthetic appeal of GRP fencing makes it a popular choice for landscaping and garden applications. It enhances the visual appeal of outdoor spaces while providing a reliable barrier.

Coastal Areas

Due to its corrosion-resistant properties, GRP fencing is well-suited for installation in coastal areas. Exposure to saltwater and high humidity can accelerate the deterioration of traditional fencing materials, making our alternative a great choice.

Utilities and Infrastructure

This fencing is used in utility installations and infrastructure projects where electrical insulation is essential. Its lightweight construction also simplifies transportation and installation in these settings

—

As the demand for durable, low-maintenance, and aesthetically pleasing fencing solutions continues to grow, GRP fencing stands out as the perfect choice. From enhancing security to beautifying outdoor spaces, it offers a modern and sustainable alternative that is both strong and versatile. As more individuals and industries recognise its benefits, GRP fencing is likely to play an increasingly prominent role in the future of fencing solutions.

Our frangible fencing is non-conductive, light-weight and manufactured in the UK. It is fully ICAO compliant, available in a series of colours and sizes, and comes with a 10 year guarantee. Call us now on 01325 355525 or email info@pollite.com to find out more.